Download this Proof of Performance

Situation

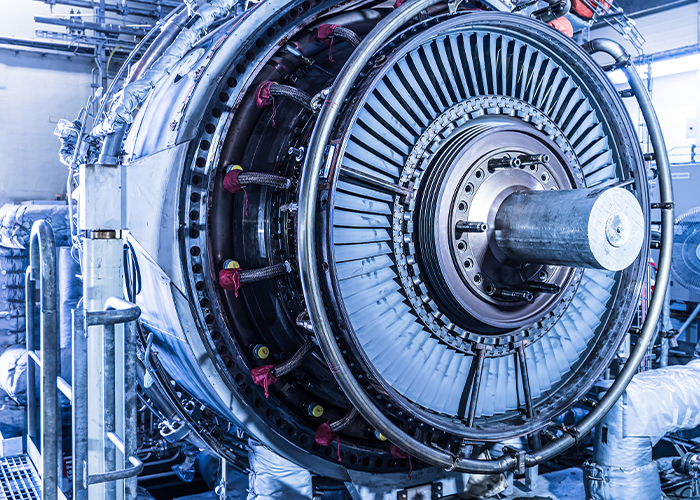

In almost every business, efficiency wins the day. This is particularly true in the petrochemical industry, where a company’s success hinges on the reliability and performance of complex machinery such as refrigerant systems and gas compressors. One petrochemical facility in Texas, in search of increased efficiency, sought out the expertise of the Mobil™ engineering team to help decrease maintenance downtime at one of their plants.

Recommendation

The Mobil team and its Integrated Lubrication Services (ILS) partner, Conco1, quickly identified a main source of the long downtime was the maintenance procedures themselves during equipment turnaround. While best practice often calls for the use of High-Velocity Oil Flushing, these procedures can be lengthy and harsh on the machinery. As a result, the team proposed a novel approach utilizing Mobil™ Solvancer® oil-soluble cleaner across various systems, including the Process Gas Compressor (PGC) Seal, PGC Lube, and Proplyne Refrigerant Compressor (PRC)/Ethylene Refrigerant Compressor (ERC) Lube Systems.

Mobil™ Solvancer® oil-soluble cleaner, which harnesses technology created in collaboration with Fluitec®, is added into machinery’s operational oil before a scheduled oil change – optimizing the state of equipment by getting rid of unwanted varnish and extending the time between system overhauls. The technology itself is cost-effective and efficient, with one of the industry's lowest* treat rates of 3-5%.

But, perhaps most importantly, Mobil™ Solvancer® oil-soluble cleaner does all this while not disrupting plant operations.

Impact

The petrochemicals plant became considerably more efficient in their service routines – seeing reductions in both the time and cost. The plant saved 3.5 days’ worth of maintenance hours per system and conserved over 20,000 gallons of oil. Additionally, MPC (Membrane Patch Colorimetry) readings post treatment were significantly lower, indicating Mobil Solvancer oil soluble cleaner technology successfully dealt with varnish and improved the overall cleanliness of the plant’s machinery.

Benefit2

The engineering team projects savings by using its novel Mobil™ Solvancer® oil soluble cleaner-powered maintenance approach to be as much as $295,000 USD annually.

1Formerly RIG. 2This success story is based on the experience of a single customer and actual results can vary depending upon the type of equipment used and its maintenance, operating conditions and environment, and any prior lubricant used.

©Fluitec. Fluitec and Solvancer are registered trademarks of Fluitec NV or one of its subsidies. Other trademarks shown are property of their respective owners. ©2024 ExxonMobil. All other trademarks used herein are trademarks or registered trademarks of Exxon Mobil Corporation or one of its subsidiaries.

* Actual results may vary depending on the type of equipment used and its maintenance, operation conditions and environment, and any prior lubricant used.