Construction businesses have always had to be nimble to remain profitable. But, given increased demands, supply chain disruptions, and workforce shortages that are causing an increase in the cost of building materials and labor in some regions of the United States, the need for smart thinking is greater than ever before.

There may be no better time than now to reassess your equipment maintenance practices to help you reduce your overall operational costs and equipment downtime. Our Mobil Serv℠ Engineering Team has shared its best practices for construction equipment maintenance, gathered from their decades of experience in partnering with businesses across the country to protect their investments in their heavy equipment.

1. Stay organized

With all the changes taking place and the increased competitiveness across the industry, it’s imperative to minimize unplanned equipment downtime. As you know, downtime can cost money and require valuable employee time, both of which continue to be limited resources. Staying organized is the key.

Keeping records of all maintenance inspections and performance issues will help address potential problems before they result in breakdowns and more easily identify the root cause of a failure to prevent similar ones from happening again. In fact, new technologies are making this easier than ever before to get ahead on managing your maintenance program.

“You should ensure that there are clear and easy-to-follow instructions for key maintenance procedures, schedules for maintenance activities, and records of what has been done by whom and when,” said Mobil Serv Engineer Rob Meldrum, who services the Indiana/Kentucky region. “This is especially important given that you may have many different people interacting with these machines at different times and locations.”

2. Find more ways to reduce human interaction with equipment

Reducing employee-equipment interaction at the job site is a major focus within the construction industry.

Re-visiting your maintenance program can help you find additional opportunities to reduce employee and equipment interaction. A good maintenance program maximizes reliability and optimizes equipment service intervals, reducing how often teams need to fix issues or maintain the equipment. Working with your equipment vendors and component suppliers can help ensure that you’re getting the most out of each piece of equipment.

“With lubrication, for example, you may be able to safely extend drain intervals to avoid having to bring that machine back into the shop just for an oil change. Our teams are well experienced in optimizing your PM schedule to help sync up with other critical inspections,” said Mobil Serv Engineer Barry Horsmann from southern Texas. “There is also a range of digital tools, like Mobil Serv℠ Lubrication Analysis, that you can use to help streamline and automate some of these processes.”

3. Streamline product inventory

Managing inventory can be one of your biggest headaches, even in the best of times. The need to track, handle and store various products can be overwhelming without the right management system in place.

Today, new base oil technology has allowed us to create multi-grade hydraulic and transmission oils that can be used in several components and allow hydraulics and transmissions to remain cooler compared to monograde oils. This allows these oils to flow better at lower temperatures and reduce the risk of cavitation in hydraulic pumps, while remaining thick enough to provide optimal hydraulic responsiveness when at normal operating temperatures.

“When it comes to lubricants, a lot has changed over the past 10 to 15 years,” said Mobil Serv Engineer Alex Morrow from the Colorado/Utah region. “Products can now be used for multiple applications, and last much longer - offering you an opportunity to streamline your inventory management process. We work with customers all the time help simplify their product mix."

4. Don’t be afraid to ask for support

One of the biggest challenges any company faces in this environment is reliable (and flexible) supply of needed parts and products. Work with your suppliers to ensure that they are still able to deliver.

“You shouldn’t be afraid to share your challenges with them and ask for flexibility when needed,” said Mobil Serv Engineer Victoria Dachille from Tennessee. “This is a difficult time for everyone, and your suppliers are there as a partner through it all.”

In the end, incorporating these best practices into your construction equipment maintenance program will allow you to reduce operational costs and equipment downtime, which will allow your business to maximize profitability today and in the future. If you have any questions for our lubrication experts, feel free to connect with us today!

Related content

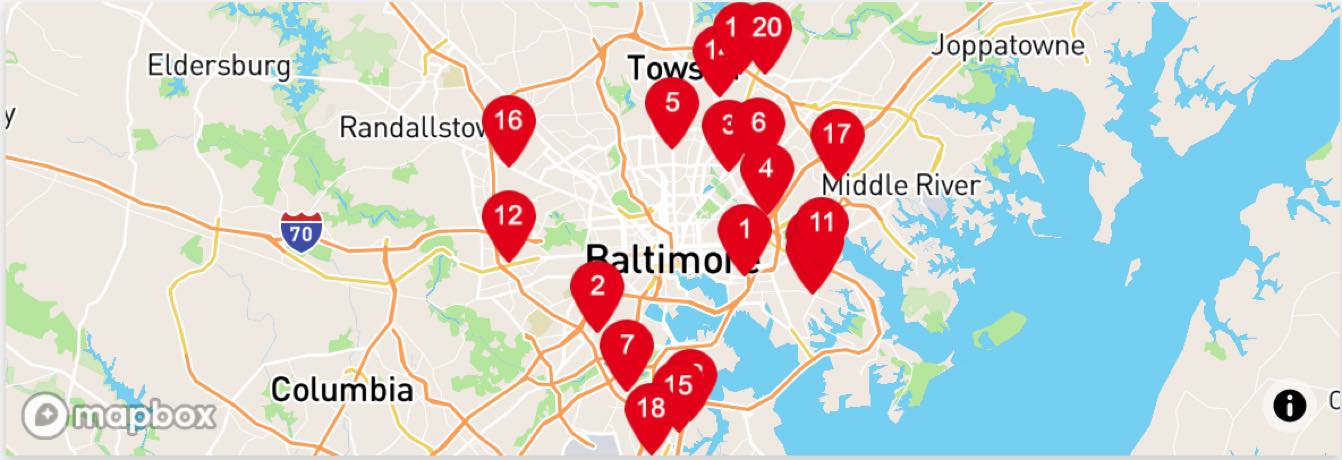

Find a lubricant distributor