Despite headwinds from the past couple of years, the construction industry outlook is cautiously optimistic. As you work with your team to capitalize on new opportunities, there are a few trends to keep in mind that can help you optimize your equipment maintenance program – ultimately helping you deliver jobs on budget, on time, and easily.

To better understand these opportunities, here are the top four trends in the construction industry:

1. Preventative maintenance programs should be predictive maintenance strategies

The construction industry has long worked to improve equipment uptime, and many companies have come to the realization that preventative maintenance (PM) programs are essential to achieving that goal.

Although considered a high priority for nearly any fleet, preventative maintenance programs still have room for improvement. Historically, PM programs were designed based on the recommendations of collaborator OEMs — which specified oil changing intervals, filter replacements and equipment inspections. Today, newer technologies, like digital monitoring and more advanced lubricant formulations, offer operators the opportunity to develop predictive maintenance programs that help extend operation time and better plan out major component replacements.

Predictive maintenance tools like Mobil℠ Lubricant Analysis leverage this technology to analyze oil quality and help detect problems before breakdowns occur — See how the analysis once helped a fleet save more than $185k.

2. The future of construction fleet maintenance is digital

Construction businesses have long stayed connected through technology, and now digital solutions are becoming more necessary as quickly as they become more sophisticated.

Much of this new technology focuses on enhanced fleet management and comes from essential OEMs, like Komatsu and Caterpillar. Their capabilities offer a range of robust solutions, all aiming to improve collaboration across the industry.

One of the challenges that comes with using technology to run a business is ensuring that all information will be organized and consistent — a difficult task if you are using multiple platforms from various OEMs combined with challenges from managing multiple jobsites.

3. Fuel efficiency is key to success

Fuel is a major cost for any construction business, and more businesses than ever are prioritizing sustainability. Finding new ways to reduce fuel consumption can have a huge impact, and more industry players, like Cat and Volvo Construction Equipment, are rolling out fuel-efficient equipment and solutions.

But improving fuel efficiency can be as easy as choosing the right lubricant. This can benefit your business by reducing fuel spend. In fact, certain hydraulic fluids can improve fuel economy by several percentage points.

For example, Mobil DTE™ 10 Excel hydraulic oil can potentially improve efficiency by up to six percent. And in hot climates, it can keep your hydraulics running cool, which improves efficiency, reduces fuel consumption, and saves you money.

In cold climates, switching from a conventional, mineral based transmission oil to a high quality synthetic, like the Mobil Delvac 1 Transmission Fluid Arctic, can help improve fuel economy by up to 3 percent.

And choosing the right lubricant has other benefits to your business as well:

- Reduced waste: you can reduce oil waste by thousands of gallons with the right, high-performance lubricant.

- Improved safety: the right lubricant will help keep your equipment running stronger and longer, so you’ll need less human/equipment interaction for maintenance and repairs.

4. Skilled labor is harder to find, and businesses need to make the most of their existing staff

Nationwide labor shortages are making it harder for construction companies to grow. Mobil Delvac™ services include staff training and product consolidation to simplify maintenance and safely extend oil drain intervals. Additionally, Mobil Delvac Modern 15W-40 Extended Performance™ engine oil can extend oil drain intervals — freeing your staff to work on more sophisticated tasks.

Related content

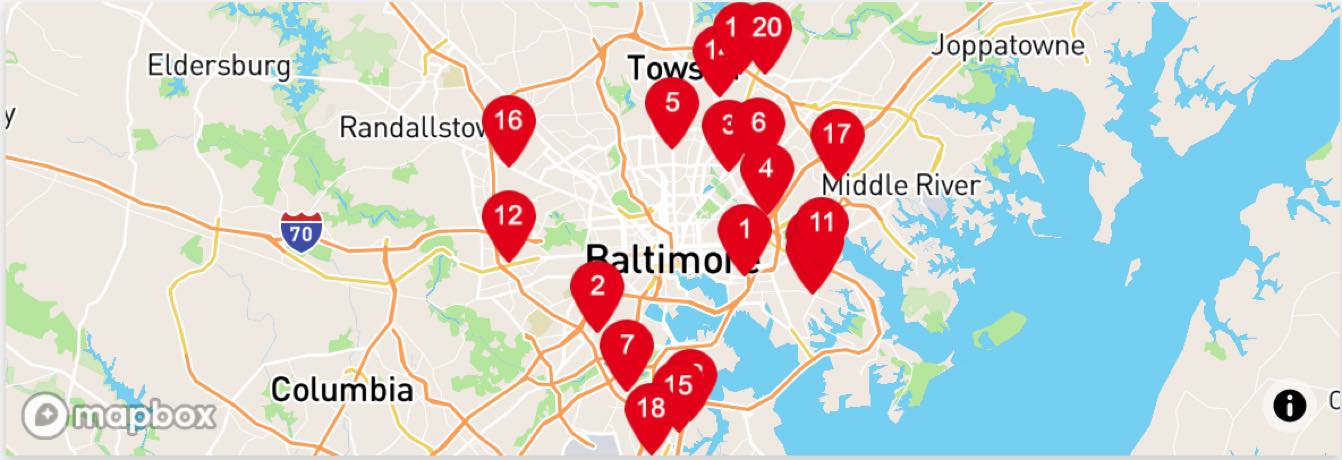

Find a lubricant distributor